Lifestyle

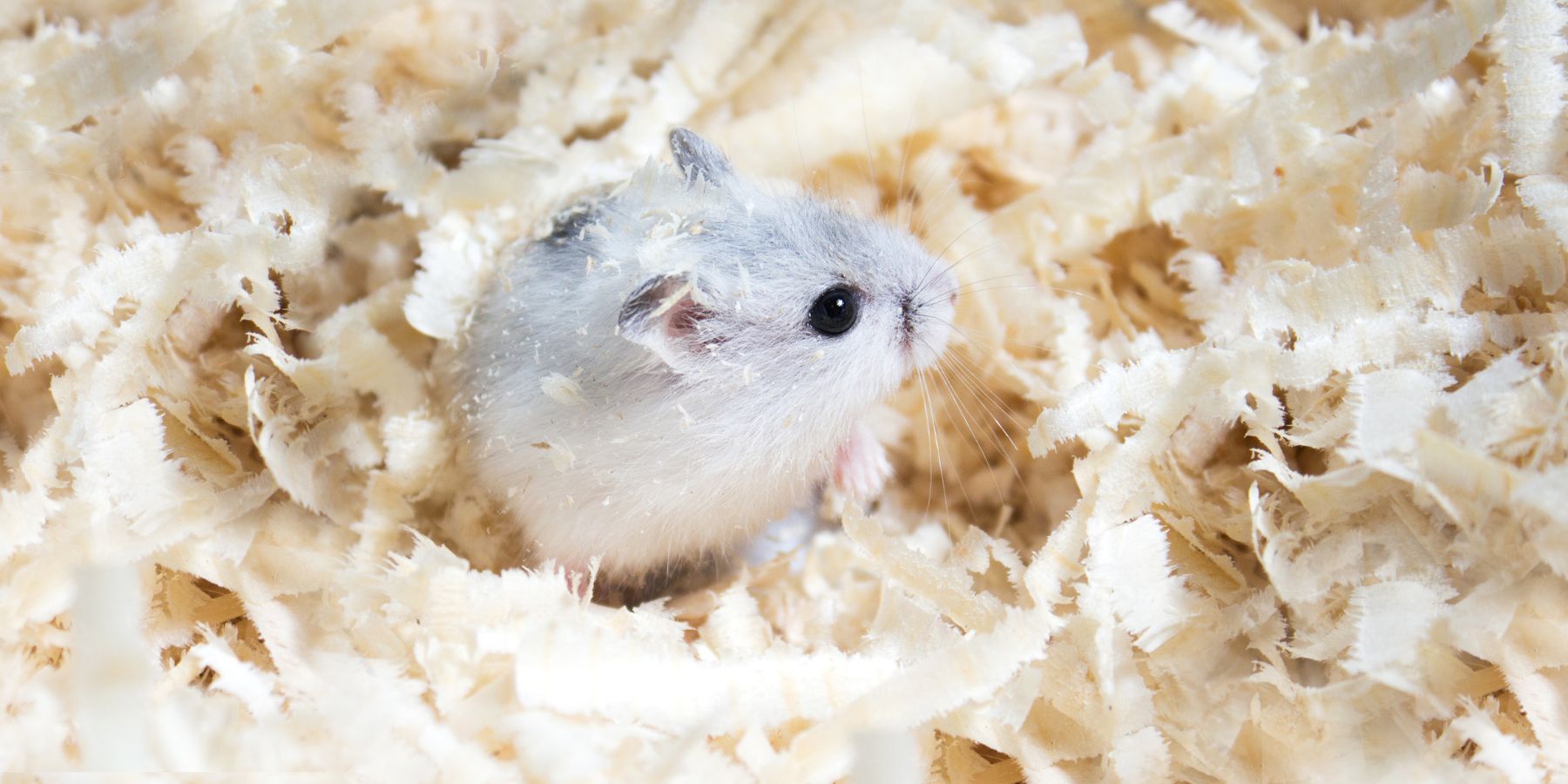

Comprehensive Guide: What Do Hamsters Need for a Happy Life?

Hamsters are popular pets, known for their playful natu [ ]

Car

The Benefits and Advantages of the 2001 GMC Jimmy Rear Differential

The significance of a reliable rear differential in a v [ ]

Lifestyle

Why do Artists Like Portable Photo Printers?

Artists frequently choose Pearl portable photo printers [ ]

News

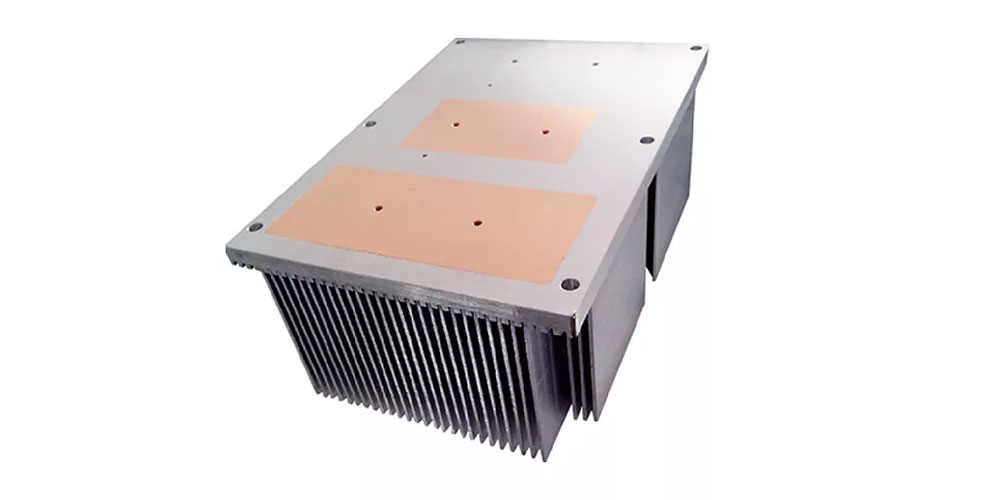

Things To Be Consider For Designing Bonded Fin Heat Sink

Digital components generate heat because they depend on [ ]

Machinery

How does a trailer boom lift give ease?

Everything is going advanced after science makes everyt [ ]

Lifestyle

What are the uses of outdoor and indoor led lighting?

An expert in lighting knows about parameters to choose [ ]

Business

What Are The Essential Things You Need To Consider When Looking For An Electric Pickup Truck For Sale?

Pickup trucks are a ubiquitous part of the American lan [ ]

Business

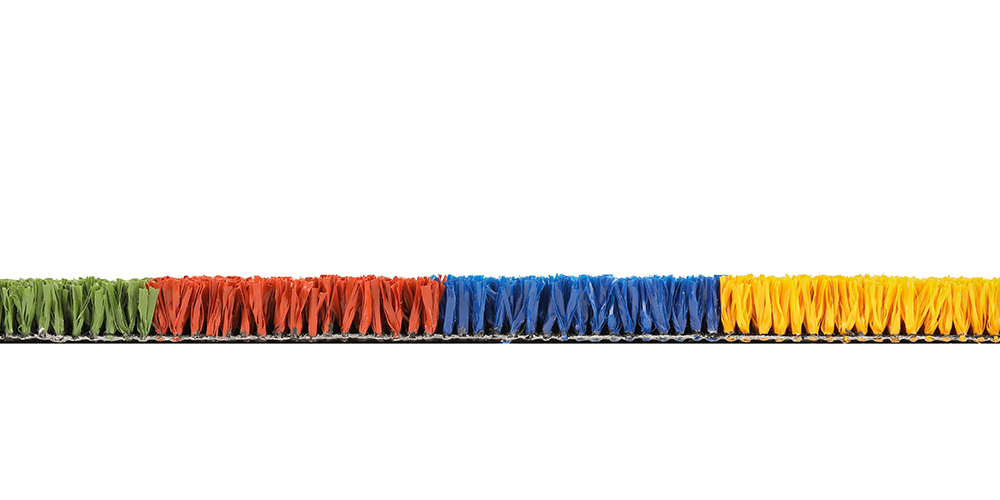

How to choose the best tennis turf?

Synthetic grass is widely used in the modern world. Bes [ ]

Lifestyle

Everything You Must Know About Garage Doors with Flush Panels

If your home has a modern or modern design, you need a [ ]

Machinery

Things To Know About A Compactor Machine

A compactor machine is one of the most useful equipment [ ]